Menu

A perfect result requires a grinding quill of extraordinary quality. For more than 50 years, Hamex has manufactured grinding quills of the absolute highest quality and precision. We are today a global supplier to world-leading manufacturers and users of CNC machines. Together with the customer, we develop just the right grinding quill optimally adapted to the special need.

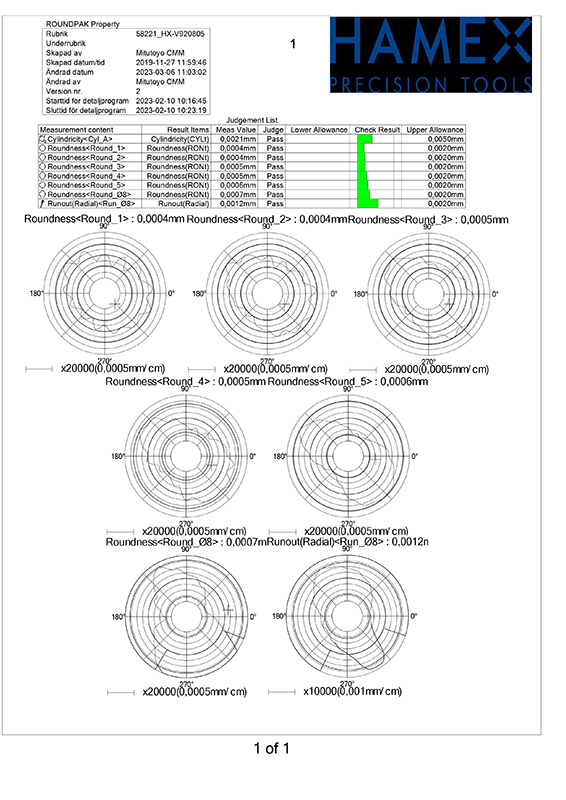

After agreement, measurement protocol attached with the delivery of the part.

Contact

Don’t hesitate, put us to the test. Start by getting in contact with me.