Meny

Specializing in Precision Grinding,

HAMEX is an expert in subcontract precision grinding services. Our grinding processes are optimized and quality-verified,

covering urgent single-unit grinding to planned serial subcontract grinding. We operate advanced, highly efficient CNC

grinding machines, as well as manual precision grinding machines managed by our experienced operators.

CNC Grinding is widely used due to its ability to produce high-precision

components efficiently and consistently, making it suitable for parts

where tight tolerances and fine surface finishes are crucial.

Customers within industries as aerospace, automotive, medical,

machine tools and die manufacturing.

Surface grinding is a precise machining process that allows for tight

control over dimensional accuracy. It is suitable for achieving

flatness and parallelism within very narrow tolerances.

Customers within needs as finishing flat surfaces, squaring up blocks

and plates, sharpening cutting tools and precision components for

machinery and tools.

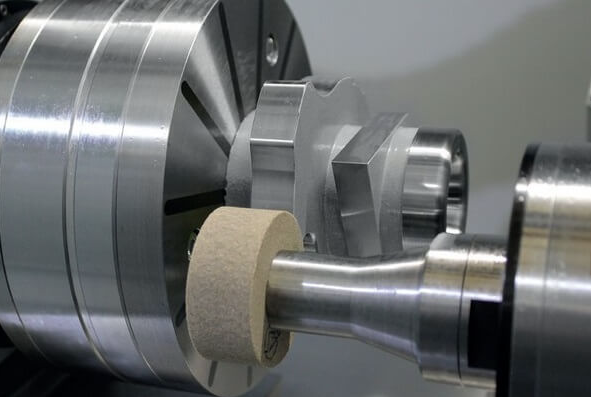

External Cylindrical Grinding is known for its ability to achieve tight

tolerances and high surface finishes. It is often used when precise

dimensional accuracy and a smooth external surface are critical for

the functionality and appearance of the part.

Customers within industries as aerospace, automotive, medical and

general manufacturing. Parts as shafts, pistons, bearings and other

cylindrical components.

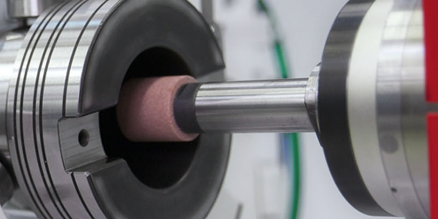

Internal Cylindrical Grinding is known for its ability to achieve tight

tolerances and high-quality internal surface finishes. This is

particularly important in applications where precise dimensions

and a smooth internal surface are critical for the proper functioning

of the part.

Customers within industries as automotive, aerospace, medical and

general manufacturing.

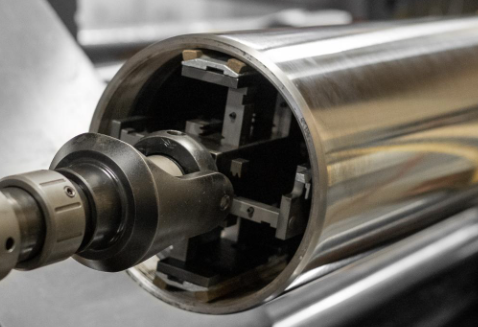

Tool Grinding contributes to improved machining efficiency, better

surface finishes and longer tool life. Regular maintenance through

tool grinding is essential for maintaining the performance and

longevity of cutting tools in various manufacturing processes.

Customers within industries as metalworking, woodworking and

machining where precision cutting tools are essential for producing

quality parts and products.

Internal & External Thread grinding is a highly specialized and

precise machining process that plays a crucial role in ensuring the

quality and accuracy of threaded components in diverse industrial

applications.

Customers within industries as automotive, aerospace and machinery

manufacturing.

Jig Grinding is a precision machining process used to create highly

accurate and intricate shapes and surfaces in metal workpieces,

that require tight tolerances and fine surface finishes.

Customers within industries as aerospace, automotive and tool and die

making.

Honing is a versatile and efficient machining process that

contributes to the production of high-quality components with

improved internal surface characteristics. It is often utilized as a

final finishing step in the manufacturing process to achieve the

desired specifications and performance of critical components.

Customers within industries as aerospace, automotive and defence.

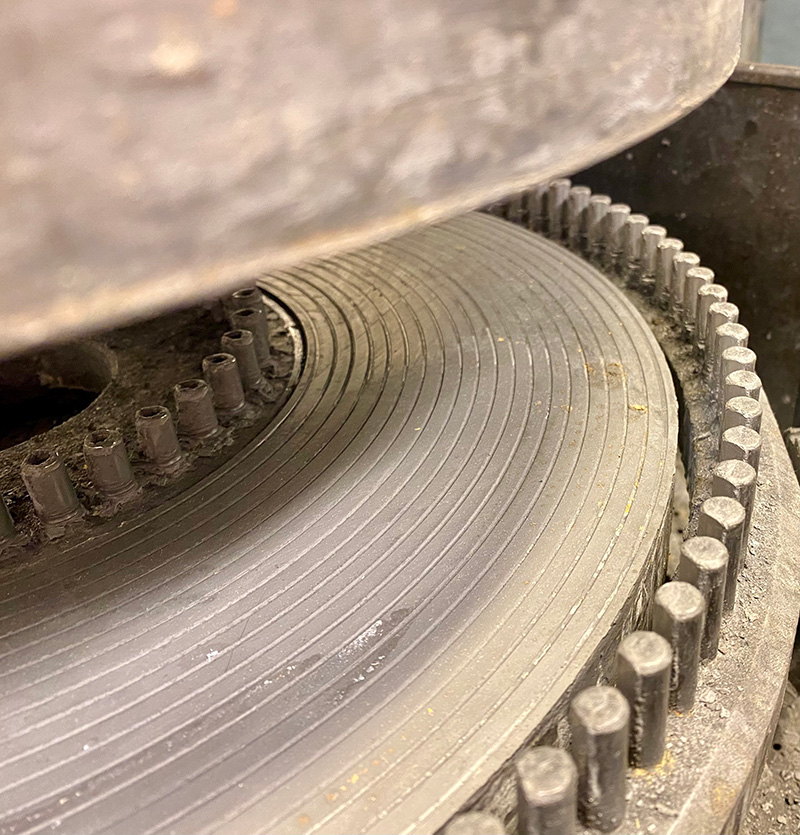

Lapping is a precision machining process used to produce

extremely flat surfaces and tight tolerances on workpieces. This

process is often employed in the finishing stages of manufacturing

to achieve high levels of flatness, surface finish and dimensional

accuracy.

Customers within various industries as defence, aerospace, electronics,

and other precision engineering.

Polishing is a finishing process used in manufacturing and

metalworking to improve the surface finish of a workpiece.

Polishing create a smooth, reflective and aesthetically surface by

removing imperfections, scratches and irregularities.

Customers within various industries and for different purposes where a

smooth and shiny surface is desired.

| Cookie | Varaktighet | Beskrivning |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| CookieLawInfoConsent | 1 year | Records the default button state of the corresponding category & the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| _lfa | 2 years | This cookie is set by the provider Leadfeeder to identify the IP address of devices visiting the website, in order to retarget multiple users routing from the same IP address. |

| Cookie | Varaktighet | Beskrivning |

|---|---|---|

| pll_language | 1 year | The pll _language cookie is used by Polylang to remember the language selected by the user when returning to the website, and also to get the language information when not available in another way. |

| Cookie | Varaktighet | Beskrivning |

|---|---|---|

| nQ_cookieId | 1 year | The domain of this cookie is owned by Albacross. It is used as a analytical tools to identify the potential customers by setting a unique Id for the customers. The session Id is used to implement the preference choice made by the customer upon their re-visit. |

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_gtag_UA_207994453_1 | 1 minute | Set by Google to distinguish users. |

| _ga_26GG6ZSXN6 | 2 years | This cookie is installed by Google Analytics. |

| _gcl_au | 3 months | Provided by Google Tag Manager to experiment advertisement efficiency of websites using their services. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| _hjAbsoluteSessionInProgress | 30 minutes | Hotjar sets this cookie to detect the first pageview session of a user. This is a True/False flag set by the cookie. |

| _hjFirstSeen | 30 minutes | Hotjar sets this cookie to identify a new user’s first session. It stores a true/false value, indicating whether it was the first time Hotjar saw this user. |

| _hjIncludedInPageviewSample | 2 minutes | Hotjar sets this cookie to know whether a user is included in the data sampling defined by the site's pageview limit. |

| _hjIncludedInSessionSample | 2 minutes | Hotjar sets this cookie to know whether a user is included in the data sampling defined by the site's daily session limit. |

| _hjTLDTest | session | To determine the most generic cookie path that has to be used instead of the page hostname, Hotjar sets the _hjTLDTest cookie to store different URL substring alternatives until it fails. |

| Cookie | Varaktighet | Beskrivning |

|---|---|---|

| NID | 6 months | NID cookie, set by Google, is used for advertising purposes; to limit the number of times the user sees an ad, to mute unwanted ads, and to measure the effectiveness of ads. |

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| Cookie | Varaktighet | Beskrivning |

|---|---|---|

| nQ_userVisitId | 30 minutes | This cookie is set by Albacross, to help with insights regarding how certain companies navigate on the site. |

| _hjSessionUser_2619130 | 1 year | This cookie is set by Hotjar, which provides recordings and heatmaps of sessions in order to identify opportunities for better user experience. |

| _hjSession_2619130 | 30 minutes | This cookie is set by Hotjar, which provides recordings and heatmaps of sessions in order to identify opportunities for better user experience. |

| _lfa_test_cookie_stored | session | Set by Leadfeeder, to provide insights about what company users adhere to. |